An innovative approach to the reusable spacecraft suggests making them “sweat” to survive the abrasor of heat duration to the atmosphere of the earth, which allows them to land ready for another flight.

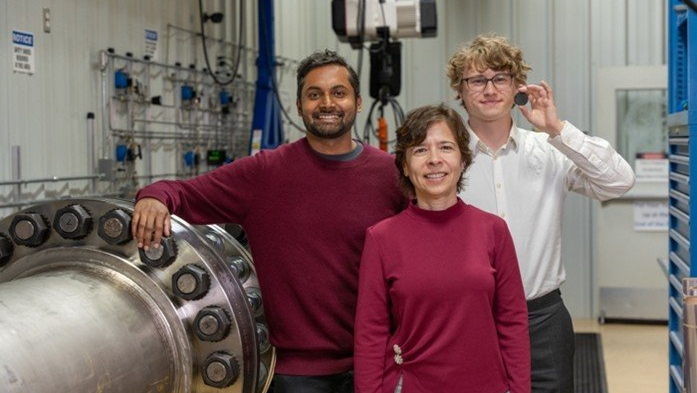

A research team from the University of Texas A&M has been associated with Canopy Aerospace to develop and try a 3D printed Material that releases or “sweats” a refrigerant gas to protect the spacecraft from the intense heat found when traveling back to Land At high speeds.

This Innovative Design Use a Method Called Transpiration Cooling, Wh goes to Layer of gas is release the vehicle’s surface that not only cools the spacecraft but also acts as a barrier prevention direct contact with friction and compression or compression or compression or compression or compression or compression or compression or compression or compression or compression or compression or Compression or Compression or Compression or Compression or Compression Or Atmospheric gases Duration Re -enters.

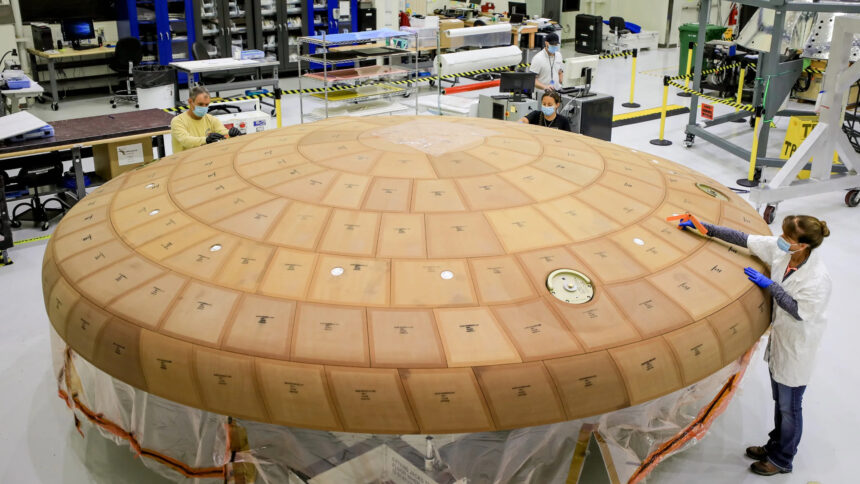

The use of gas as an insulator for the spacecraft could replace the traditional unique use Heat shields That burn or heat resistant ceramic tiles that must be replaced between flights, making the spacecraft more full and quickly GigableAccording to a statement from the University of Texas A&M.

“The gas has a very low thermal conductivity,” said Hassan Saad IFTI, an assistant professor of aerospace engineering in The statement. “This is the reason why a jacket to implap is so effective. They catch the air in these pockets, so it is the isolation of the air that keeps you hot, not the solid part of the jacket.”

THE NEW MATERIAL – A 3D printed Silicon carbide developed by Canopy Aerospace: is designed to be strong enough to withstand extreme atmospheric pressures, but porous enough for the sudo refrigerant. The prototypes are being tested in the university to evaluate the ability of the “sweating” material and how well the gas that is released to the isolated is released a spacecraft.

“We should see that the surface of the material is cooler. Hypersonic speeds When the refrigerant flow is introduced that the baseline when there is no refrigerant present, “William Matthews, a fourth year doctoral student who leads the tests, he said in the statement. Help us to decide which one we want to go.”

This research is part of a technology transfer subsidy of small Air Force companies of $ 1.7 million.